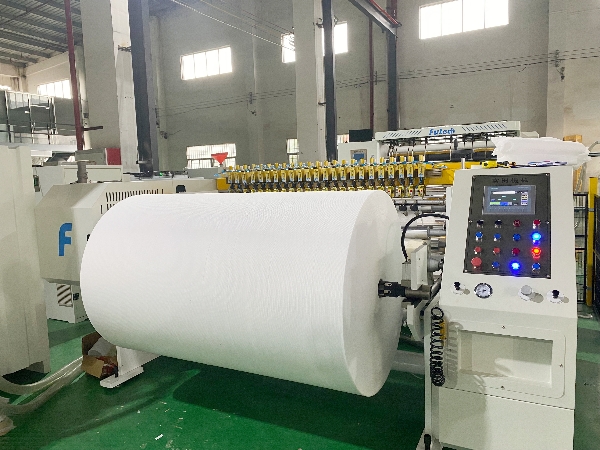

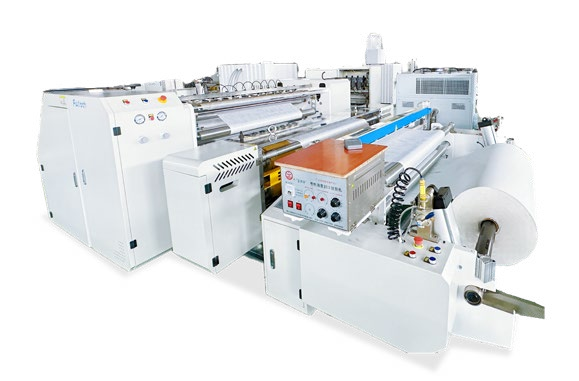

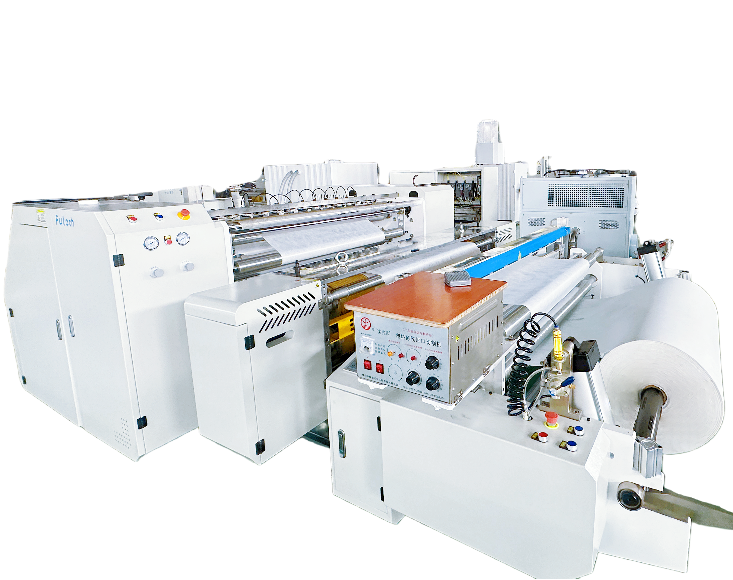

●Servo-driven nonwoven embossing perforating machine for spunbond/hot-air nonwoven. Automatic tension control, on-line slitting, ideal for diaper/medical production.

Description

DK1200-00/1600-00 Nonwoven Embossing & Puncherforating Machine is a cutting-edge, ISO/CE-certified solution for the global nonwoven processing industry (hygiene, medical products), featuring high-precision servo drive, imported PLC, and integrated automatic tension closed-loop control to avoid material stretching/wrinkling, ensure ≥99.5% qualification rate, and handle materials like spunbond/hot-air/SMS/SMMS; it also has an on-line slitting device to reduce waste to ≤3% (vs industry 8-10%), plus localized after-sales support, helping manufacturers in India/Europe/Southeast Asia boost efficiency, quality and competitiveness.

|

Material width

|

1200 ~ 1600mm

|

|

Mechanical speed

|

70m/min

|

|

Max embossing speed

|

50-60m/min |

|

Unwinding diameter

|

Maxφ900mm

|

|

Rewinding diameter

|

Maxφ700mm

|

|

Minimum slitting width

|

100mm

|

|

Applicable material

|

SS/SSS non-woven 18g-40g

|

Application

Features

- Servo Drive Precision: Adopts high-precision servo drive system, ensuring stable operation at high speed (up to 180m/min) and uniform embossing/perforating—core advantage of servo-driven embossing machine for nonwoven.

- Automatic Tension Control: Integrated closed-loop tension control system dynamically adjusts tension to prevent nonwoven stretching/wrinkling—solving key pain points for automatic tension control nonwoven perforating machine.

- On-line Slitting for Profit: Built-in on-line slitting device reduces material waste to ≤3% (vs. 8-10% industry average), directly increasing clients’ profit margins—key value of on-line slitting nonwoven processing machine.

- Multi-Material Compatibility: Suitable for spunbond, hot-air, SMS/SMMS nonwovens (20-120g/m²), serving as both spunbond nonwoven embossing machine and hot-air nonwoven perforating equipment.

- Customizable Processing: Interchangeable embossing rollers and perforating dies support custom patterns and hole sizes, adapting to small-batch personalized orders.

- International Quality Compliance: ISO and CE certified, meets EU REACH and US FDA standards—qualifying as ISO CE certified nonwoven embossing machine for global export.

- Intelligent Operation: Imported programmable controller with HMI touchscreen, supporting parameter memory (50+ recipes) and one-click operation—reducing training time for operators.

- Localized Support: On-site installation within 72 hours in key markets (India, Southeast Asia), with 24-hour technical support and free operation training—solving cross-border service delays.

Elevate Your Global Hygiene Production with Patented Tech!

Contact our regional sales teams for a free demo, compliance guide tailored to your market, or customized quote. We offer on-site installation, operator training in local languages, and 1-year global warranty with localized service support.