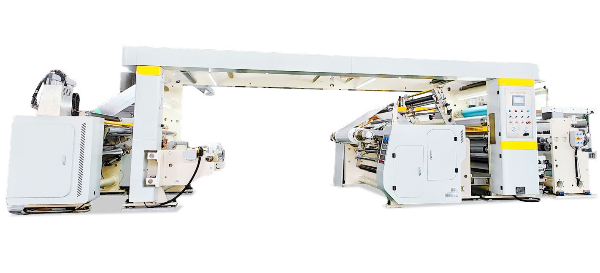

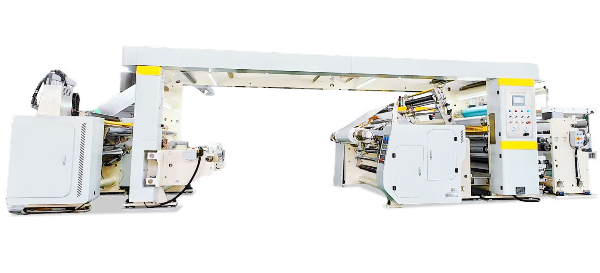

●High-Speed PUR Hot Melt Adhesive Coating Laminating Machine,ISO/CE certified,for medical PE/nonwoven,solvent-free, ideal for hygiene product production globally.

Description

Our PUR Hot Melt Adhesive Coating Laminating Machine series covers five core models, including:

●German Nordson Slot Die Coating Laminating Machine

●PUR Adhesive Coating Laminating Machine

●Hot Melt Adhesive Coating Laminating Machine

●Solvent-Free Coating Laminating Machine

●Solvent-Based Precision Coating Machine

Meets needs of the medical and hygiene industry. As professional PUR Hot Melt Adhesive Coating Laminating Machine solutions, all models adopt advanced coating technology—with solvent-free options complying with global environmental standards and precision models meeting high-end medical quality requirements.

This high-speed PUR hot melt coating machine series integrates precise coating, uniform laminating, and stable winding functions, enabling efficient production of composite materials such as PE+nonwoven, nonwoven+film, and multi-layer nonwovens.

Optimized for the Indian and global hygiene markets, each model features intelligent PLC control, adjustable coating thickness, and compatibility with specific adhesives, ensuring consistent quality for disposable protective clothing, surgical gowns, and sanitary napkins. Backed by ISO and CE certifications, this cost-effective hot melt laminating solution delivers "Chinese prices, European-quality performance," empowering manufacturers to enhance production efficiency, reduce operational costs, and gain a competitive edge in the global marketplace.

|

Machine Model |

Core Coating Technology |

Suitable Adhesive Type |

Max Laminating Speed (m/min) |

Applicable Substrates |

|

Slot-die Coating Laminating Machine

|

Slot-die coating

|

PUR hot melt adhesive, EVA hot melt adhesive |

300mpm |

PE, nonwoven, PP film, PET film |

|

PUR Adhesive Coating Laminating Machine |

Gravure roller transfer coating

|

PUR hot melt adhesive (polyurethane) |

300mpm |

PE, nonwoven, cotton fabric, leather |

|

Hot Melt Adhesive Coating Laminating Machine |

Gravure roller transfer coating

/Slot-die coating

|

EVA, PO, PUR hot melt adhesive |

300mpm |

Nonwoven, PE, PP, paper |

|

Solvent-Free Coating Laminating Machine |

Gravure roller transfer coating |

Solvent-free polyurethane adhesive |

300mpm |

Nonwoven, PE, aluminum foil, PET |

|

Solvent-Based Precision Coating Machine |

Gravure roller transfer coating |

Solvent-based acrylic adhesive, polyurethane adhesive |

150mpm |

Film, nonwoven, paper, metal foil |

Application

Features

Elevate Your Global Hygiene Production with Patented Tech!

Contact our regional sales teams for a free demo, compliance guide tailored to your market, or customized quote. We offer on-site installation, operator training in local languages, and 1-year global warranty with localized service support.