●Full set supporting units for PE cast film extruder: drying, auto dosing, MDO, recycling. ISO certified, ideal for breathable/non-breathable film production.

Full Supporting Units Description

Full Supporting Units Description

|

Unit Name

|

Key Functions

|

|

Key Functions

|

Remove moisture from PE resin to prevent film bubbles/pinholes.

|

|

Auto Dosing System

|

Precise proportioning and feeding of raw material.

|

|

MDO Unit

|

MDO stretching to enhance film tensile strength & toughness. |

|

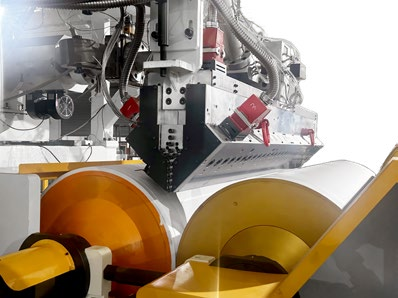

Edge Trim Recycling Machine (Crusher/Chip/Granulator)

|

Crusher/Chip/Granulator edge trims for direct reuse in extrusion

|

|

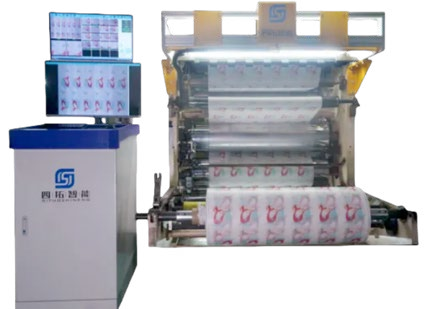

Defect Inspection System

|

Real-time detection of pinholes, spots, thickness deviation

|

|

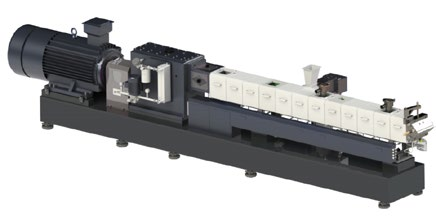

Breathable Compounding Extruder

|

Compound PE resin & additives to produce breathable masterbatch

|

●Drying System: As a key drying system for PE resin, it adopts hot air circulation drying technology with precise temperature control (80-120℃). It effectively removes moisture from PE resin and masterbatch, reducing film defects like bubbles and pinholes to below 0.1%. The closed-loop design saves 30% energy compared to ordinary drying systems, with a maximum capacity of 500kg/h to match large-scale extrusion lines.

●Auto Dosing System: This auto dosing system for PE film extrusion is equipped with 4-6 hoppers and high-precision load cells (dosing accuracy ±0.1%). It automatically proportions PE resin, CaCO3 masterbatch, and functional additives, avoiding manual proportioning errors that cause film performance instability. The HMI touchscreen supports 100+ formula memories, enabling quick switching between breathable and non-breathable film production.

●Oil-Temp Machine: As a critical oil-temp machine for PE extruder, it uses thermal oil circulation to control the temperature of the extruder barrel and screw (±1℃). It avoids local overheating that causes material degradation, ensuring uniform melting of PE materials. The high-temperature version (up to 300℃) is compatible with modified PE materials for high-performance non-breathable films.

Finishing & Unloading Units

●Auto Unloading & Shaft Pulling System: This system automatically unloads finished rolls (max weight 500kg) and pulls out the winding shaft, replacing manual operation and reducing labor costs by 50%. The hydraulic lifting design ensures stable unloading, avoiding roll damage during handling.

Elevate Your Global Hygiene Production with Patented Tech!

Contact our regional sales teams for a free demo, compliance guide tailored to your market, or customized quote. We offer on-site installation, operator training in local languages, and 1-year global warranty with localized service support.