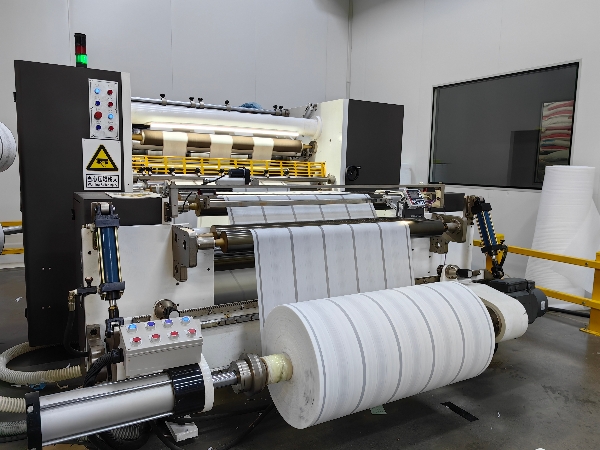

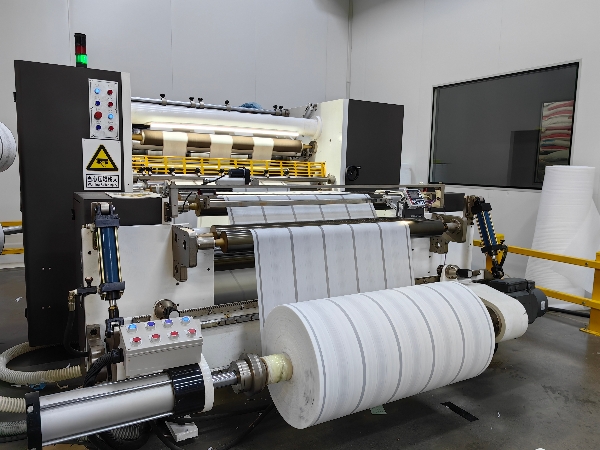

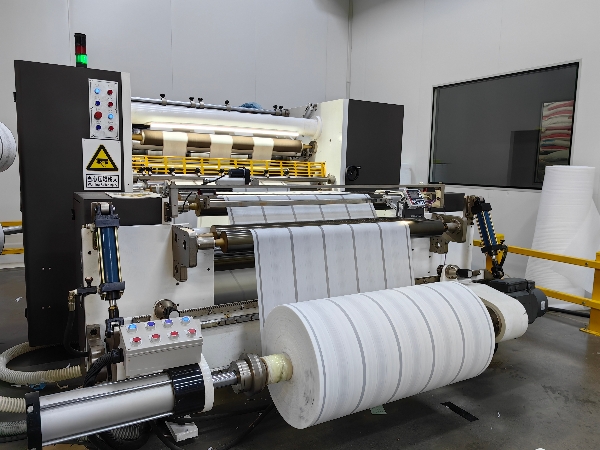

High-Speed Slitter Rewinder Machine for Precision Film Processing(600m/min Performance)

Description

Our High-Speed Slitter Machine is the ultimate solution for finishing breathable PE films, medical non-wovens, and flexible packaging. We pushes the boundaries with a heavy-duty reinforced frame that eliminates vibration at 600m/min. Our commitment to precision web control means even the thinnest hygiene films are processed without wrinkling or over-stretching. Whether you are upgrading from seeking a more cost-effective high-end solution, our slitter rewinders deliver the accuracy and speed your factory 4.0 environment demands.

-

-

Low-GSM hygienic breathable non-breathable PE film slitting equipment

Machine Model

|

Max width of material

|

Max diameter of winding/unwinding

|

Min efective width of slitting

|

Unwinding and loading form

|

Winding and loading form

|

Slitting speed

|

Slip Shaft Slitting Machine

|

1200-2400mm

|

800mm

|

100mm

|

3" key type air shaft

|

3" Slip shaft

|

500mpm

|

Air Shaft Slitting Machine

|

1200-2400mm

|

800mm

|

100mm

|

3" key type air shaft

|

3" key type air shaft

|

300mpm

|

Application

This versatile slitting machine series, a key medical hygiene film slitting equipment, is widely used in:

●Medical hygiene products:

Slitting of breathable PE film for surgical gown liners, non-breathable PE film for medical packaging, and micro-perforated film for wound dressing covers.

●Disposable sanitary products:

Cutting of PE films for diaper backsheets (breathable), sanitary napkin side panels (non-breathable), and adult incontinence pad packaging.

●Light industrial hygiene:

Slitting of PE films for disposable bed sheets, cleaning wipes, and food hygiene covers.

Features

●Dual Model Flexibility: Slip shaft model for precision thin-film slitting (±0.1mm) and air shaft model for high-speed thick-film processing (320m/min), covering all hygienic PE film needs.

●High Precision & Low Waste: Automatic tension control and sharp carbide blades ensure uniform slitting; seamless roll change reduces waste to ≤2%, qualifying as low-waste PE film slitting equipment.

●High-Speed Operation: Air shaft model reaches 320m/min, slip shaft model 280m/min—30% faster than standard slitting machines, boosting daily output by 5–8 tons.

●Intelligent Control: Siemens PLC and touchscreen interface enable one-click parameter setting, formula memory (stores up to 50 recipes), and real-time fault alarms, simplifying operation.

●Durable & Reliable: International brand components and anti-rust thickened frames ensure a service life of 12–15 years (vs. 8–10 years for peers); annual downtime ≤20 hours.

●International Compliance: ISO and CE certified, meeting medical hygiene standards (EU REACH, US FDA), eligible for global export as ISO CE certified high-speed slitting machine.

●Localized Support: Dedicated service teams in India and Southeast Asia provide on-site installation within 72 hours and 24-hour technical support, avoiding cross-border delays.

Elevate Your Global Hygiene Production with Patented Tech!

Contact our regional sales teams for a free demo, compliance guide tailored to your market, or customized quote. We offer on-site installation, operator training in local languages, and 1-year global warranty with localized service support.

Global Headquarters Email: cassielfung21@gmail.com | Helplines: . +0086-13622527012