Description

FlyYou’s DS Technology PE Non-Breathable Cast Film Extrusion Line integrates advanced international tech (including U.S. DS equipment core craftsmanship), decades of manufacturing experience, and exclusive patents—redefining standards with features like a high-precision oil-heated mold temperature controller, optimized screw for PP/high-filler feeding, ABC three-layer structure, AB shaft turret winding, 70-80mm ultra-narrow slitting, ISO/CE certifications, and flexible formula switching to meet strict medical/hygiene industry demands for quality, efficiency, and compliance, ideal for global markets like India.

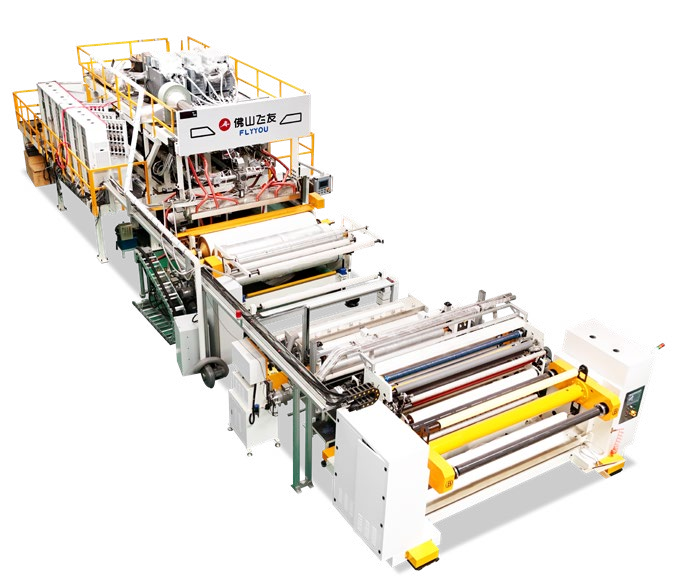

Low GSM Non-Breathable Film Manufacturing Machine

|

Width Range

|

1000-3800mm

|

|

Machine Speed

|

200m/min

|

|

Product Gsm

|

10-40g

|

|

|

LDPE,HDPE,LLDPE,Color masterbatch,Filler,PP,ect.

|

|

Min Online Slitting Size

|

70-80mm ultra-narrow cutting

|

|

Screw Heating and Cooling Method

|

Oil temperature machine control

|

|

Winding Tpe

|

AB shaft turret winding unit

|

|

Machine Wall Panel

|

CNC machining

|

|

Machine Dimensions

|

|

Application

-

This DS Technology PE Non-Breathable Cast Film Extrusion Line is a versatile disposable hygiene product film manufacturing line and medical grade PE cast film production machine, widely applied in:

-

Medical field: Production of films for medical protective clothing, surgical gowns, surgical underpads, and sterile packaging.

-

Disposable hygiene products: Manufacturing backsheets, side panels, and packaging films for adult diapers, sanitary napkins, and sanitary pads.

-

Other scenarios: Customized film production for hygiene-related products requiring high barrier properties, low GSM, and strict quality control standards.

Features

-

-

-

-

High-Precision Oil Temperature Control: Adopts oil heating mold temperature controller, ensuring uniform PE melting and no material degradation—core advantage of our oil temperature control PE cast film machine.

-

High-Filler Feeding Optimization: Innovatively structured screw designed for PP substrate and high-percentage filler composite feeding, standing out as a top-tier high-filler PE film extruder.

-

ABC Three-Layer Structure Support: Enhances film strength, stiffness, and barrier properties, making it a leading ABC three-layer structure PE cast film equipment for high-end hygiene backsheets.

-

Waste-Reducing Winding System: AB shaft turret winding with high-speed flipping technology, a key feature of our AB shaft turret winding film production line that minimizes transition waste.

-

Precision Ultra-Narrow Slitting: 70-80mm high-speed online slitting, meeting the needs of users searching for ultra-narrow slitting PE film extrusion machine.

-

Durable & Compliant: Adopts international brand parts and thickened wall panels; ISO and CE certified to qualify as a reliable ISO CE certified PE non-breathable film machine.

-

Flexible Application: On-demand formula switching to adapt to both medical and disposable sanitary product scenarios, serving as a versatile disposable sanitary product film extruder.

Elevate Your Global Hygiene Production with Patented Tech!

Contact our regional sales teams for a free demo, compliance guide tailored to your market, or customized quote. We offer on-site installation, operator training in local languages, and 1-year global warranty with localized service support.

Global Headquarters Email: cassielfung21@gmail.com | Helplines: . +0086-13622527012