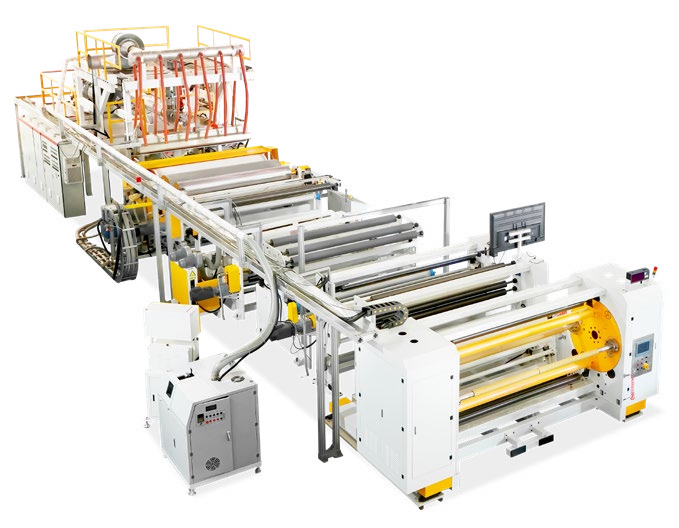

Industry-Proven Reliability with Taiwan advanced design

- High Quality Output: Specifically optimized to produce high-quality non-breathable PE films used for premium diaper backsheets and sanitary napkins.

- High-Speed Stability (Up to 250m/min): Reinforced frame and precision chill rolls allow for continuous, vibration-free operation at maximum industrial speeds.

- Precision Thickness Control: Integrated online gauging and automatic die-head adjustments ensure a uniform film profile across the entire web width.