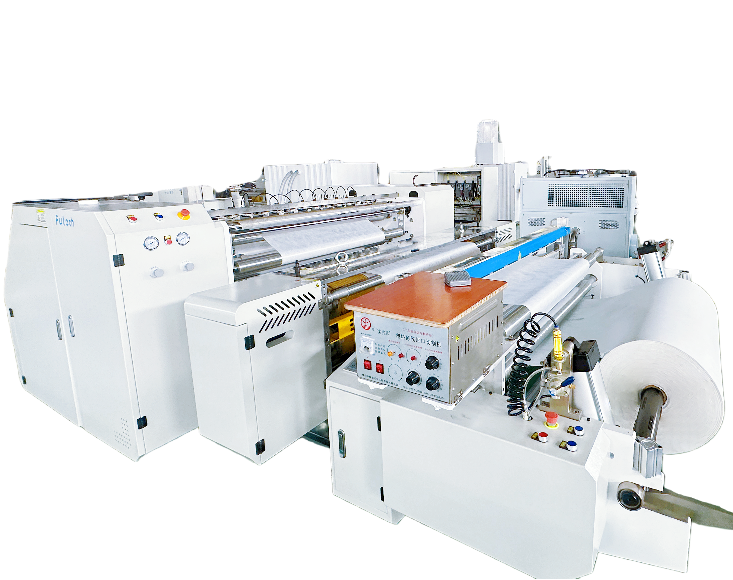

Nonwoven 3D Embossing & Perforating Machine for Premium Top Sheets

The Global Solution for 3D Perforated Nonwoven Production

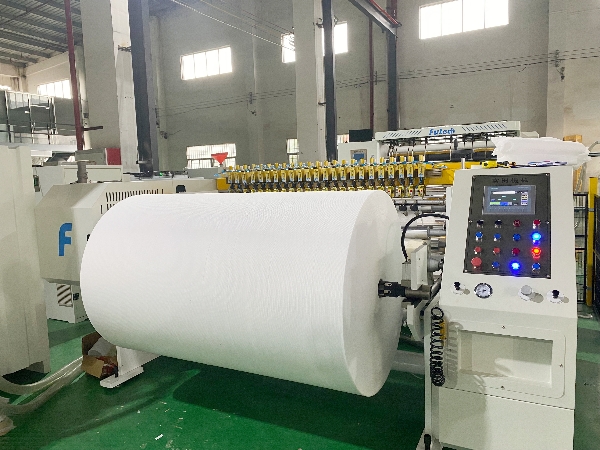

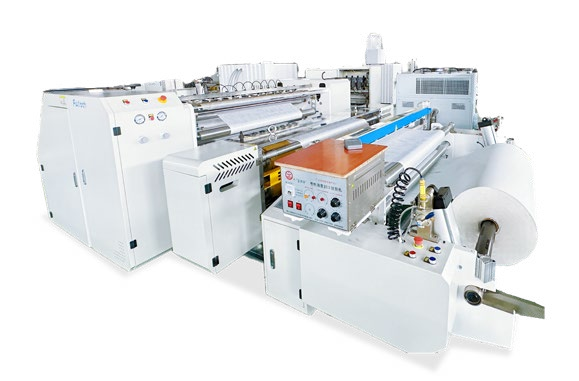

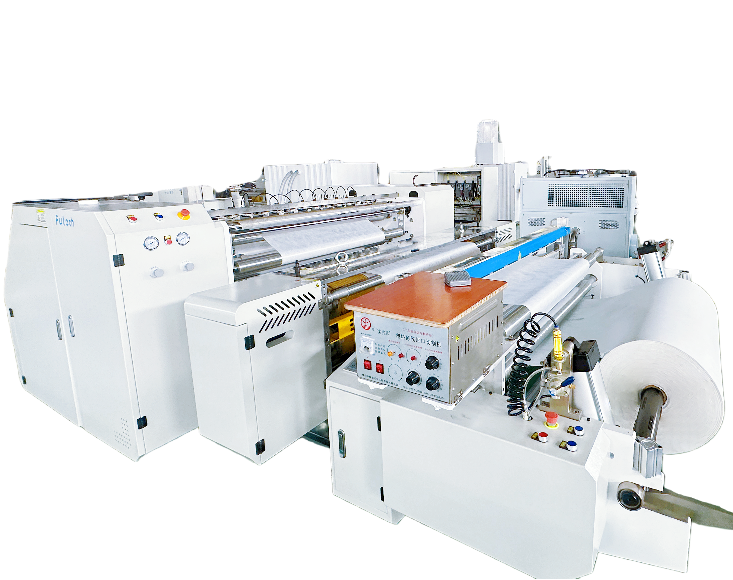

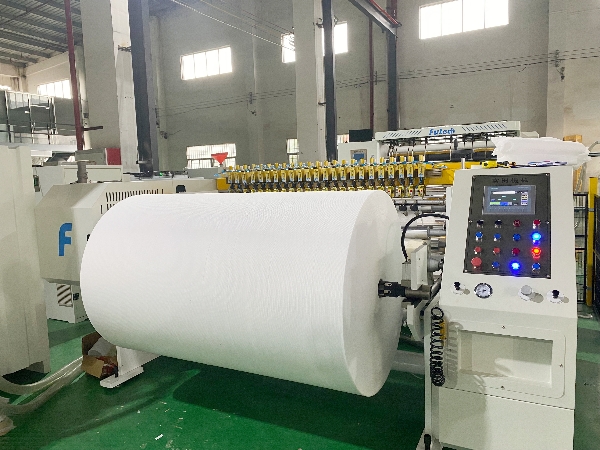

The Nonwoven 3D Embossing & Perforating Machine is designed for manufacturers who prioritize the "Top Sheet" experience. In the competitive hygiene market, the 3D texture and breathability of the liner are key to consumer preference. our machine excels in processing Spunbond, SMS, and Hot-Air through nonwovens. Our unique heating and cooling process "locks in" the embossed shape, ensuring that the 3D effect remains prominent. Whether you are upgrading your sanitary napkin line or baby diaper facility, futech provides the high-speed stability (70m/min) and pattern precision required for the next generation of hygiene products.

-

-

Spunbond nonwoven embossing machine

|

Material width

|

1200 ~ 1600mm

|

|

Mechanical speed

|

70m/min

|

|

Max embossing speed

|

50-60m/min

|

|

Unwinding diameter

|

Maxφ900mm

|

|

Rewinding diameter

|

Maxφ700mm

|

|

Minimum slitting width

|

100mm

|

|

Applicable material

|

SS/SSS non-woven 18g-40g

|

Application

-

This versatile machine series, a key equipment for nonwoven processing, is widely applied in:

-

●Disposable hygiene products: Processing of spunbond/hot-air nonwoven for diaper top sheets (embossing for softness)、sanitary napkin surface layers (perforating for breathability)、adult incontinence pad materials, and hygiene wipe substrates.

-

●Medical products: Embossing and perforating of SMS/SMMS nonwoven for medical mask inner layers (breathable holes), surgical gown fabrics (reinforced embossing), and sterile dressing materials (uniform perforating for moisture permeability).

-

●Other nonwoven fields: Processing of nonwoven materials for baby wipes, cosmetic pads, and industrial filter fabrics (custom embossing/perforating as per demand).

-

Features

- Servo Drive Precision: Adopts high-precision servo drive system, ensuring stable operation at high speed (up to 180m/min) and uniform embossing/perforating—core advantage of servo-driven embossing machine for nonwoven.

- Automatic Tension Control: Integrated closed-loop tension control system dynamically adjusts tension to prevent nonwoven stretching/wrinkling—solving key pain points for automatic tension control nonwoven perforating machine.

- On-line Slitting for Profit: Built-in on-line slitting device reduces material waste to ≤3% (vs. 8-10% industry average), directly increasing clients’ profit margins—key value of on-line slitting nonwoven processing machine.

- Multi-Material Compatibility: Suitable for spunbond, hot-air, SMS/SMMS nonwovens (20-120g/m²), serving as both spunbond nonwoven embossing machine and hot-air nonwoven perforating equipment.

- Customizable Processing: Interchangeable embossing rollers and perforating dies support custom patterns and hole sizes, adapting to small-batch personalized orders.

- International Quality Compliance: ISO and CE certified, meets EU REACH and US FDA standards—qualifying as ISO CE certified nonwoven embossing machine for global export.

- Intelligent Operation: Imported programmable controller with HMI touchscreen, supporting parameter memory (50+ recipes) and one-click operation—reducing training time for operators.

- Localized Support: On-site installation within 72 hours in key markets (India, Southeast Asia), with 24-hour technical support and free operation training—solving cross-border service delays.

Elevate Your Global Hygiene Production with Patented Tech!

Contact our regional sales teams for a free demo, compliance guide tailored to your market, or customized quote. We offer on-site installation, operator training in local languages, and 1-year global warranty with localized service support.

Global Headquarters Email: cassielfung21@gmail.com | Helplines: . +0086-13622527012