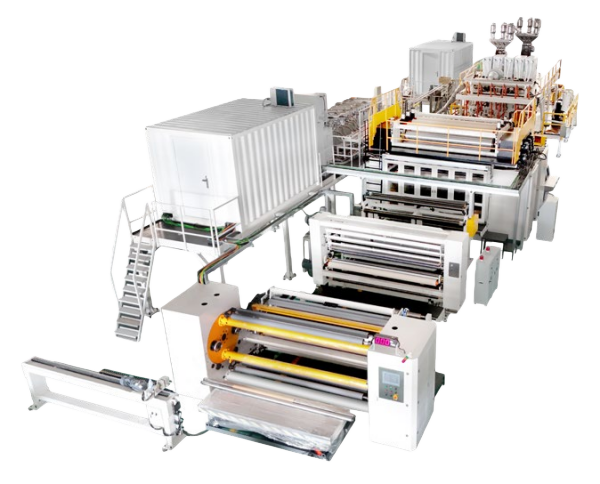

High electricity costs in South Africa are a key concern for local enterprises, making our energy-saving casting machine highly popular. A Johannesburg medical hygiene material manufacturer bought 2 cast film line. Their previous film extrusion line consumed high kWh per ton of film, while our machines with frequency conversion motors and high-efficiency heaters only consume lower kWh per ton—a 25% energy saving.

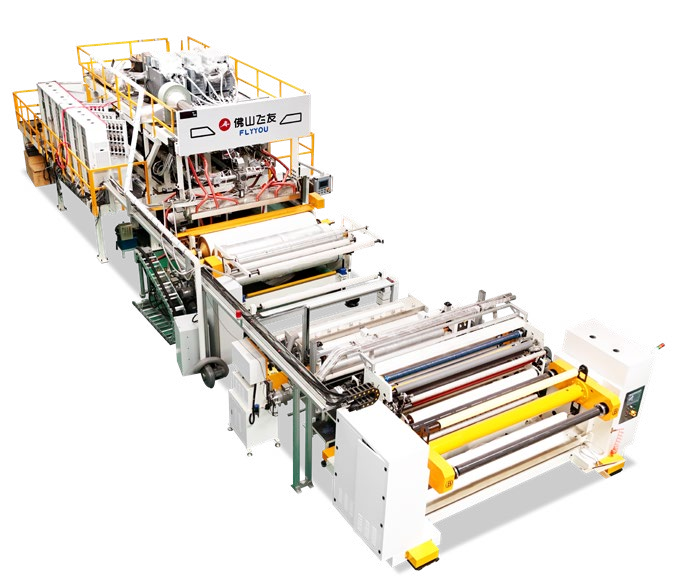

Largr US dollars in monthly electricity cost savings. The films produced have excellent barrier properties, meeting South Africa's standard, helping them win contracts with two major local hospitals. A Cape Town enterprise focusing on pharmaceutical material purchased 1 extrusion machining, noting that the equipment's precise thickness control (±0.01mm) ensures consistent film quality, which is crucial.